As part of our promise to our customers, we stick to heritage methods that use a little bit of technology and a lot of tradition, intended to make milled products that are as close as possible in flavour and nutritional content to the unmilled grains.

1. Local Grain

We grow all of our grain on our farm located just past Kakabeka Falls.

2. Storage Bins

At harvest time we harvest the grain and dry it in storage bins for one to two weeks, depending on how humid the weather’s been.

3. The Cleaner

From the storage bins the grain moves through the cleaner, where screens filter out everything except perfectly-sized grains. The grain is brought up to room temperature and further dried before it makes its way to the first mill.

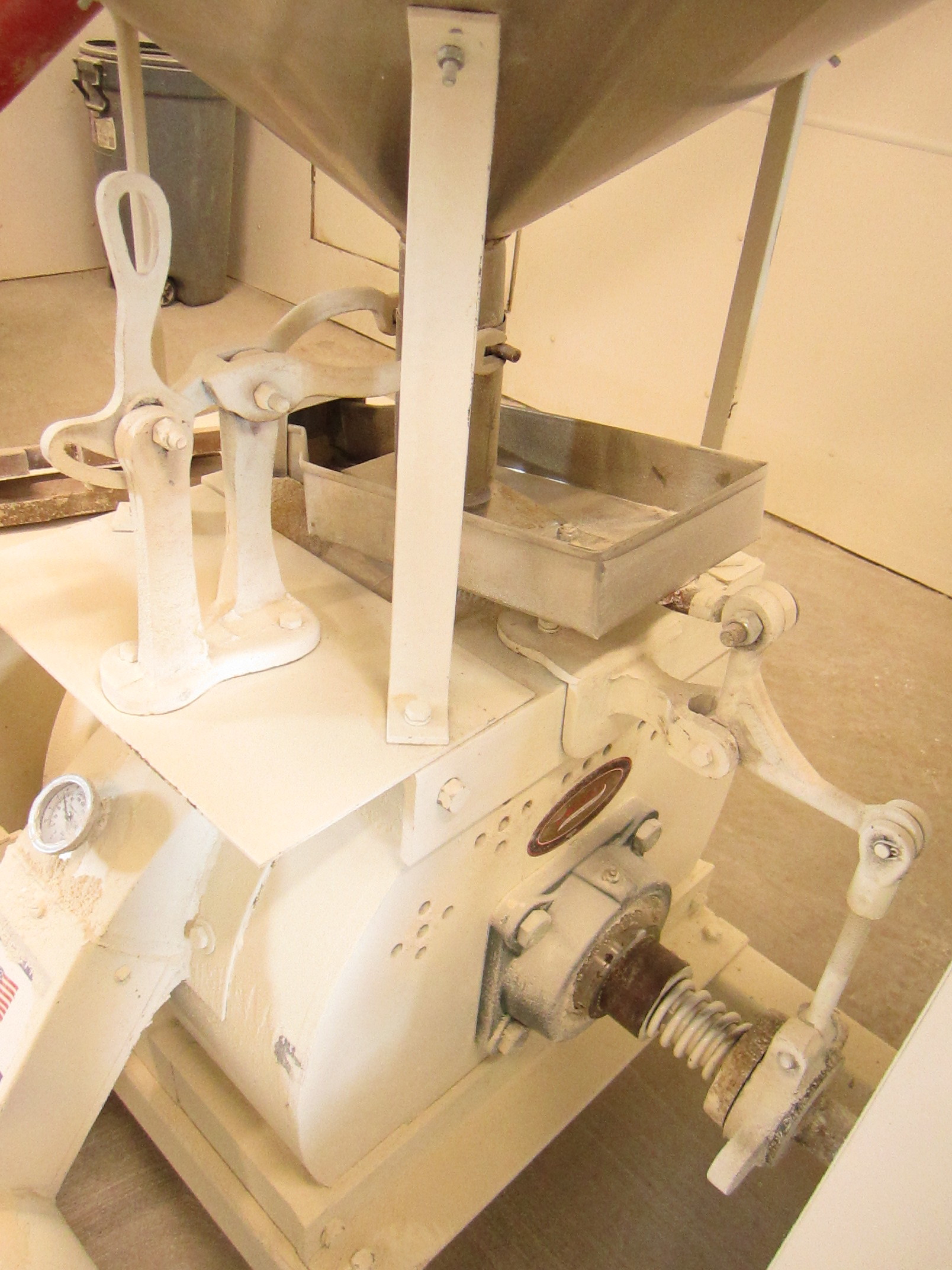

4. First Mill

We grind our grain with two electric mills with pink granite stones. The first mill uses 12” stones with a wider gap between them, so the grains heat up only slightly during their first grinding.

5. Second Mill

The grains cool down as they flow through to the second mill, where 20” stones with a smaller gap grind the flour to the fine consistency our customers enjoy. This gentle, two-step process keeps our tasty grains from overheating as they’re milled so our flour retains the majority of its flavour, proteins and nutrients.

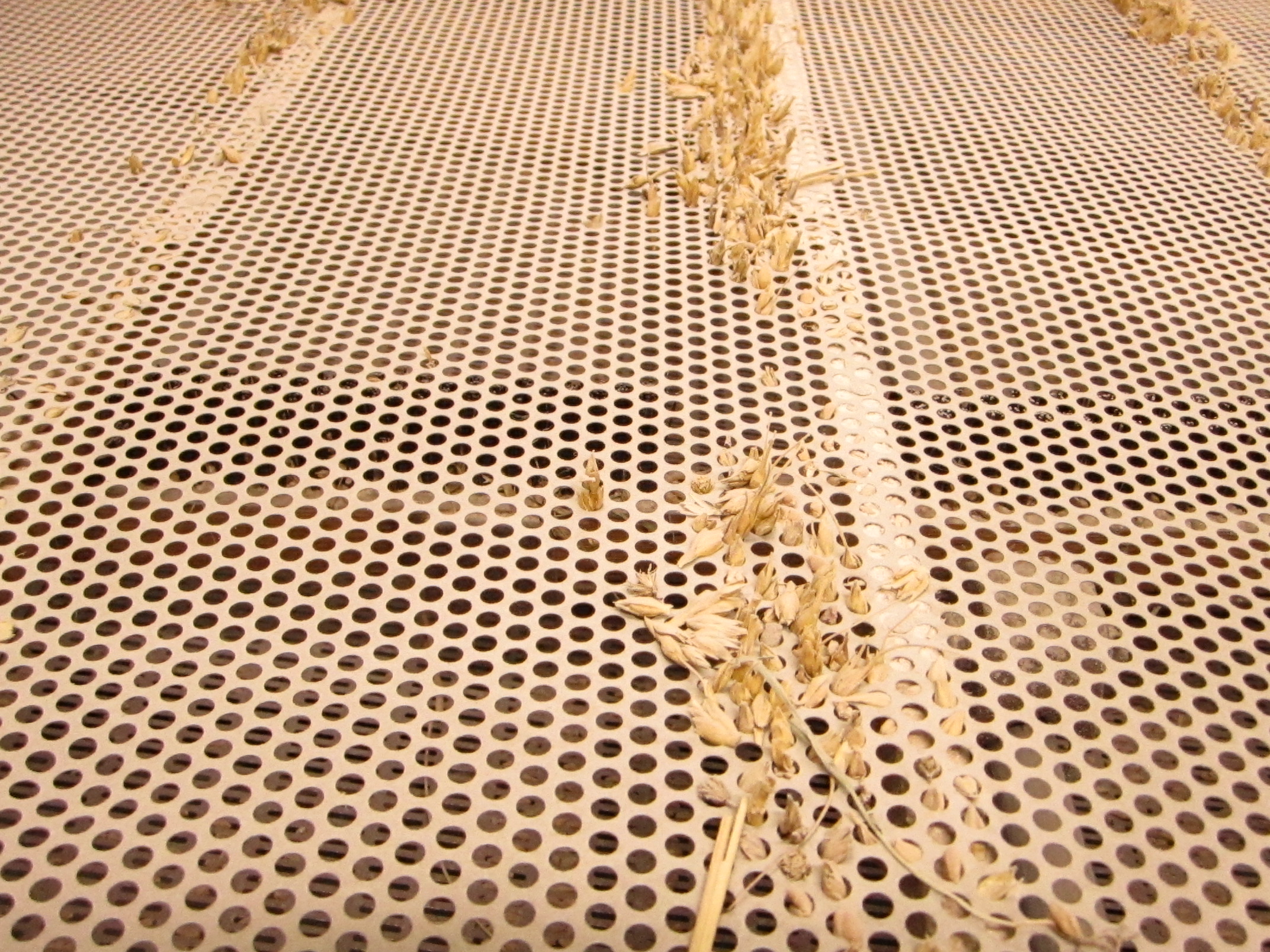

6. The Sifter

After milling all of our flour goes to the sifter. This is where the coarse bran is removed when we’re making Partially Sifted Flour. Despite its name, Whole Wheat Flour is sifted as well; a coarser screen leaves the bran but removes any remaining impurities.

7. The Bagger

From the sifter, our flour is bagged. Weights cut off the flow of flour when the bags are full.

8. Finished Product

Our finished products are sent out to restaurants, grocery stores, bakeries and retail locations. Find a retail location ›